Using the highly developed software for gear shaping machines and the Num hardware for motion control, engineering specialists have brought an old gear shaping machine with manual control up to present-day control standards.

The DePe Gear Company Ltd in Stoke-on-Trent, Staffordshire, is specialised in areas such as the development, manufacture and modernisation of gear wheels and gears for a wide range of industrial and commercial applications. These include among others the steel-processing industries, railways, mining, stone-processing and aeronautical industries. In its factory in Stoke-on-Trent the company uses a large number of gear-cutting machines, gear-shaping machines and gear grinding machines. After buying from the Stanko-Maschinenhandels GmbH a Russian gear-shaping machine used for the manufacture of large internal gears for the wind turbine industry, the Depe Gear Company asked the Euro CNC Ltd in Bromyard, Herefordshire, to carry out the necessary modernisation.

Euro CNC is specialised in retrofitting, converting and up-grading machines. For these engineering specialists, this often includes refitting manually controlled machines with CNC part- or complete systems. For this reason EURO CNC works very closely together with Num AG which can offer the very latest in CNC-technology, control software, digital drive and motors. This company, based in Switzerland, works mainly on a number of high-end CNC applications. „We have been working together with Num for 5 years, and we know that their CNC products are extremely reliable“, says Tim Clarke. „We also benefit from the excellent support we get from their subsidiaries in Great Britain“, continues the manager from Euro CNC, „and we have recently had the same experience with Num USA. Up till now we have installed PC ProCam in around 25 machines, mainly in gear hobbing rather than gear shaping machines. We have been very pleased with the positive feedback from our customers.“

In the past few years Euro CNC has accumulated a significant amount of technical knowhow about machine tools used for the manufacture of gear wheels, and works in the meantime on a wide range of hobbing and gear shaping machines: In spite of the completely mechanical function of the Stanko machine, the engineering specialists at EURO CNC were in full agreement: Fitting new motors and drives, including high-performance digital units for all axes, in combination with a CNC system permitting flexibility in use, plus an individual control surface to replace the obsolete mechanical switching device would confer great advantages.

In conventional gear-shaping machines a complex cam-type drive with a „turning„ arrangement of axes is used, in which the cutting tools are, during milling, moved along the gear-wheel blank. This means that the stroke has to be synchronised with the rotation of the tool and of the blank. This procedure has numerous disadvantages: Up to 3 axes must be used, of which each can be a source of error. Moreover, this system is extremely complicated and time-consuming and does thus not correspond to the requirements for a fast and flexible change which modern manufacturing demands. For this reason, the experts at Euro CNC have developed a completely new type of cam axis based on an entirely new form of linear actuator. The final position, length and speed of the stroke can be changed at will using the software control. The innovative and programmable exchange system of the cam axis reduces the time required for product-change from hours to just a few minutes and in this way significantly raises productivity.

In addition to the cam axis, the gear shaping machine has 3 rotation axes, which are responsible for the rotation of the cutting tool and the gear-wheel blank as well as the withdrawal of the cutting tool during build-up. In addition, the machine features a linear positioner based on a motor and a ball screw, which transports the gear wheel blank to the cutting tool. All axes are controlled by NumDrive C-servodrives and brushless Num motors.

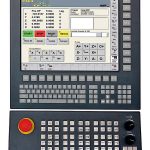

In order to control all 5 machine axes, Euro CNC uses a Num Axium Power CNC-System connected to a Num industrial computer and to a large touchscreen. The software incorporates the high-performance Numgear-pack and in this case is used mainly for the provision of the function of the electronic drive, in order to synchronise the rotation of the cutting tool, the gear wheel blank and the linear stroke axis. The control panel for the gear shaping machine is based primarily on a special version of the PC ProCam-software, which Euro CNC has developed together with the Num subsidiary in USA specially for this type of application. The software combines a sensitive and intuitive graphical user-surface which uses common concepts of gear shaping, together with a dialogue-orientated program. This means that it can be quickly learned by machine-operators even if these are not familiar with CNC machines.

The modernised Stanko gear shaping machine is currently working in the DePe Gear Company works in Stoke-on-Trent. The staff there were already familiar with Num, as three of the current gear cutting machines are fitted with Num Axium CNC systems and Numgear software. Apart from minor teething troubles the machine has been working perfectly.

„We use the gear shaping machine for a number of internal gears, including spur-gears for the drive in wind turbines, and also for many spline gears“, says Michael Parker. „Even though it is still too early for quantified data“, continues the technical director of the DePe Gear Company, “we are definitely benefitting from a reduction in time required for setting up and for operation. As in the cases of our other CNC machines, the great advantage lies in the enormous flexibility of this fully digital application which by means of software control helps us to achieve simple changes of the various types of gear wheel. Machine operators no longer have to count the number of gear-teeth that they have cut, but simply press the appropriate button in the menu which leads to maximization of throughput.„ Lb

Teilen: